More efficient by design than the strongest magnets following six requirements for maximum efficiency.

Superior products for pressure lines & gravity flow applications in three designs.

See if our Super Nova 100% Rare Earth Magnetic Separators are right for you.

Tested to be 20% stronger and more efficient at removing unwanted magnetic contamination.

Industries We Magnetically Protect and Serve

We Protect Your Brand Name

Your Product... Your Customers... Your Process Equipment

Grain

Food

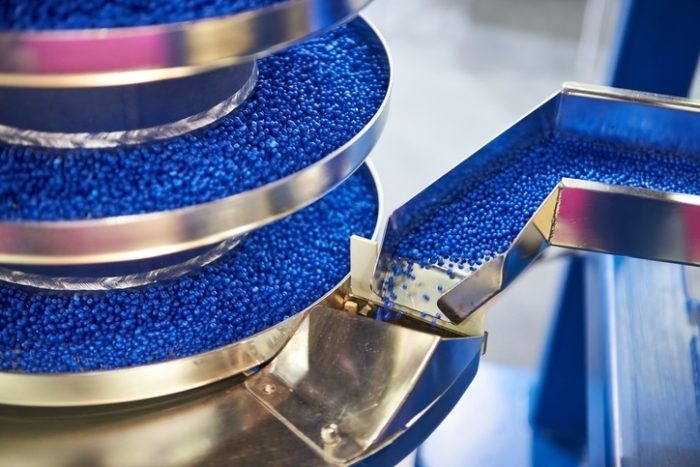

Chemical

Pharmaceutical

Plastics

Recycling

MADE IN THE USA

Direct contact magnet design captures and holds metal contamination away from product flow

Superior magnetic separators

See how our proprietary separators excel above our competitors

Free Consultation

Contact a magnetic application specialist to find out what Innovative Magnetics can do for you.