SIMILAR IN DESIGN CONCEPT & FEATURES

Gravity Flow GRT Series & Pneumatic PNT Series Magnetic Separators

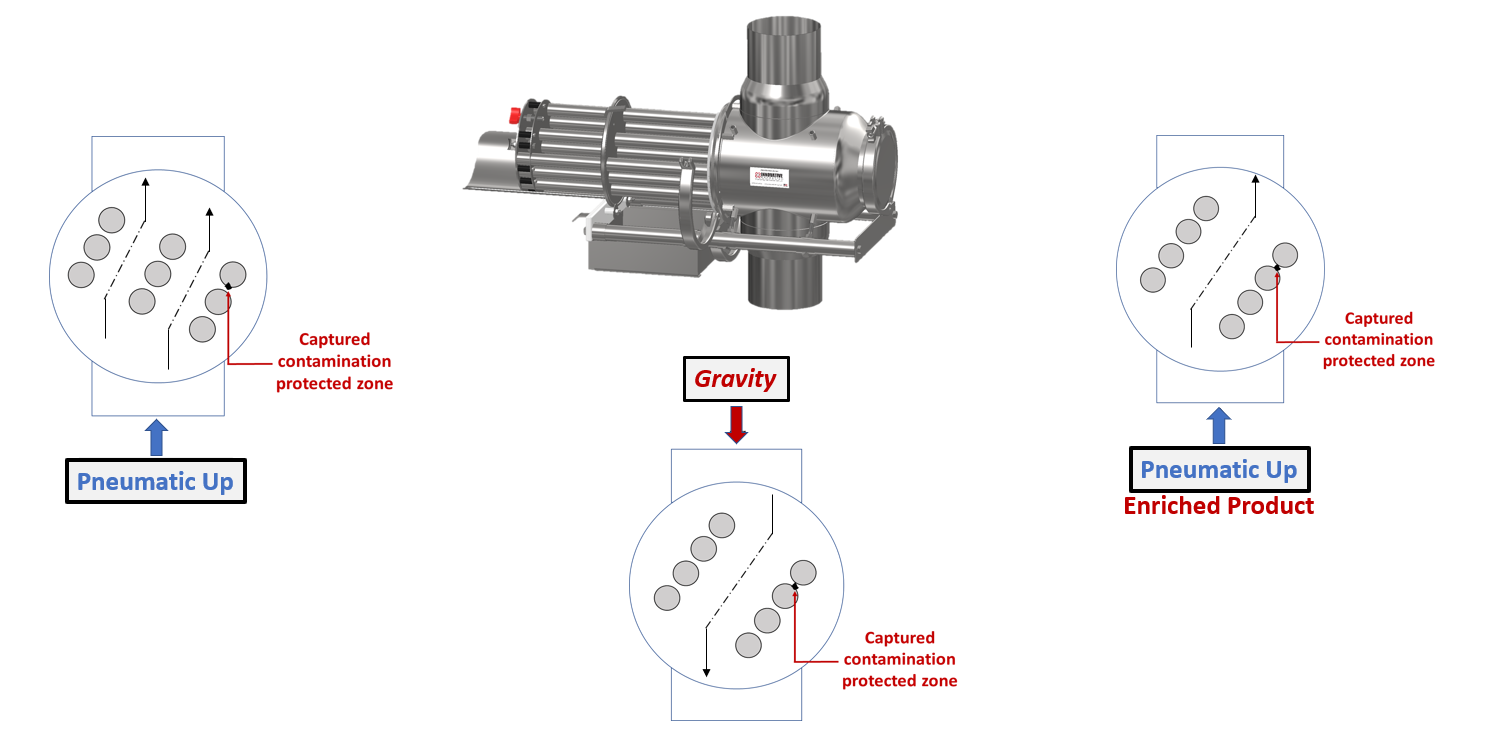

Product can not exit Series GRT & PNT magnetic separators without first directly contacting and flowing along powerful (stronger tested) angled magnet paths that capture & hold contamination out of product flow.

PNT Series Pneumatic with Additional Magnets Adds Magnetic Retention Time Compensating for Increased Velocity

PNT Series Pneumatic Flow are leak proof to 40PSI

GRT Series Gravity Flow are dust tight & leak proof

Six (6) Magnetic Separation Requirements for Maximum Efficiency

More Efficient By Design Than the Strongest Magnets

- Direct Magnet / Product contact, never only relying on the magnetic field

- Super Nova 100% Rare Earth Magnets that test strongest (126+ oz, 7.87 lbs pull on a 0.25" steel ball)

- Magnets positioned to protect captured contamination from product flow

- Product velocity is slowed & controlled in the magnetic zone

- Agitation provided by the design frees contamination from product

- Magnetic retention time is increased on the magnet & in the magnetic zone

Lower strength bulky & heavy (Ceramic or Alnico magnets) are not the only cost affective answer

We don’t offer Ceramic or Alnico Magnets

We do offer lower cost alternatives!

MAXIMUM MAGNETIC PROTECTION

DIRECT CONTACT MAGNET DESIGNS

- SUPER NOVA 100% RARE EARTH MAGNETS

- Tested 20% Stronger than all others

- Product is slowed, re-directed and

- Agitated by magnet positioning

- MAXIMUM MAGNETIC PROTECTION

Captured Contamination Flows to Protected Zones Between Magnets Out of Product Flow

Captured contamination is easily discharged by sliding the magnet assembly outside the housing product zone, releasing contamination when the magnets are pulled out of the assembly to the supplied catch pan.

Magnetic strength alone without effective separator design will not provide the most effective contamination removal.

Product is slowed, re-directed and agitated by magnet positioning in all choices

Learn More

Click below to learn more about the features, dimensions, and capacity of our magnetic separators or view Innovative Magnetics' forced gauge pull testing results.

Contact Us

See how our simplified innovative designs can help make your business more efficient. Contact a magnetic application consultant today.