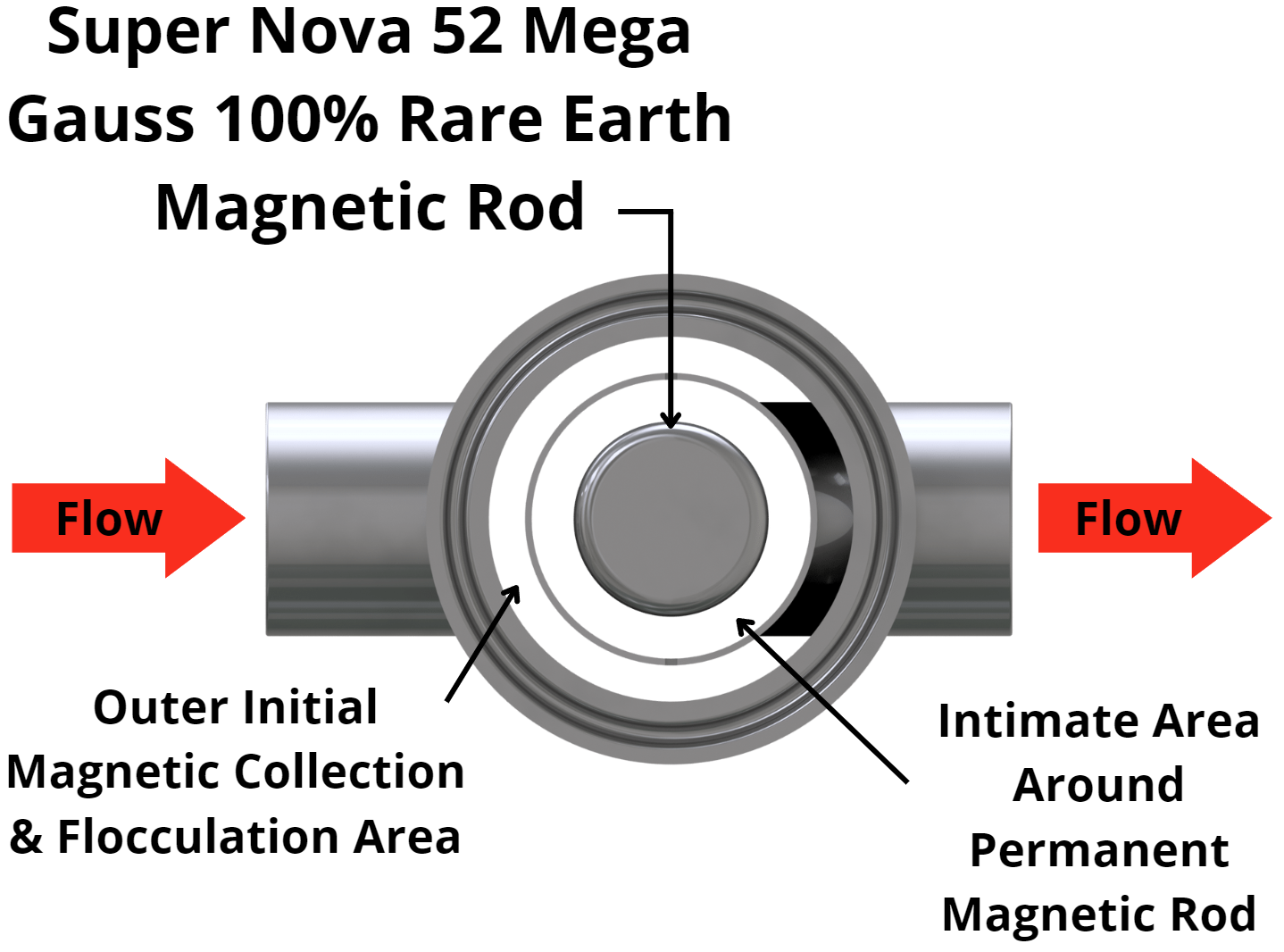

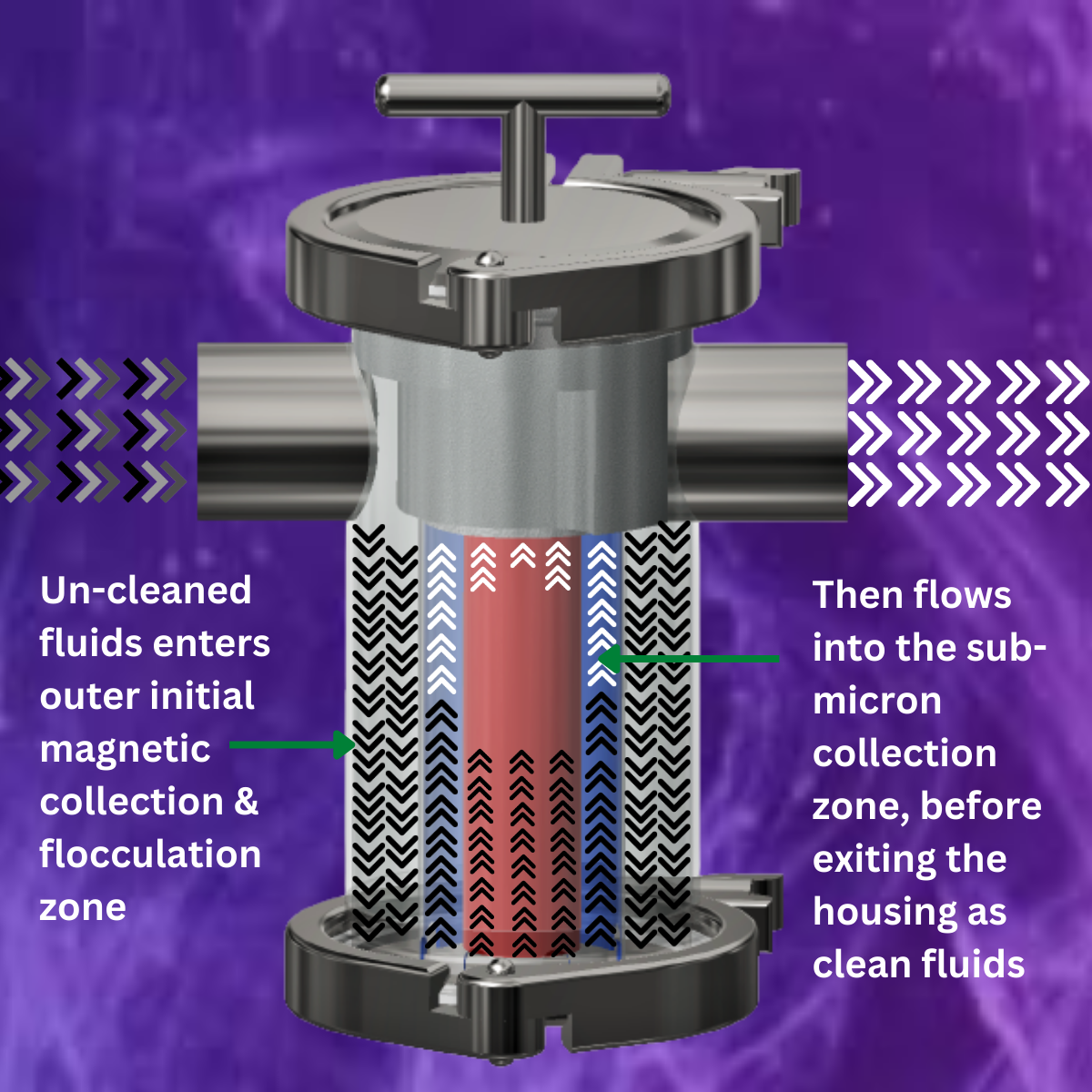

Larger heavier ferrous and stainless steel machined contaminants will sink to collection sumps. The remaining fine and micro-fine contamination particles can float. They than enter the magnetic filters flocculation zone and essentially become tiny magnets that are easily captured . The smallest of these particles staying in suspension, flow from the flocculation zone into the intimate magnetic collection zone for capture by 52 mega gauss (52,000 gauss magnets) incorporated into the strong circuits of the magnetic rod

(10) beneficial reasons & cost savings

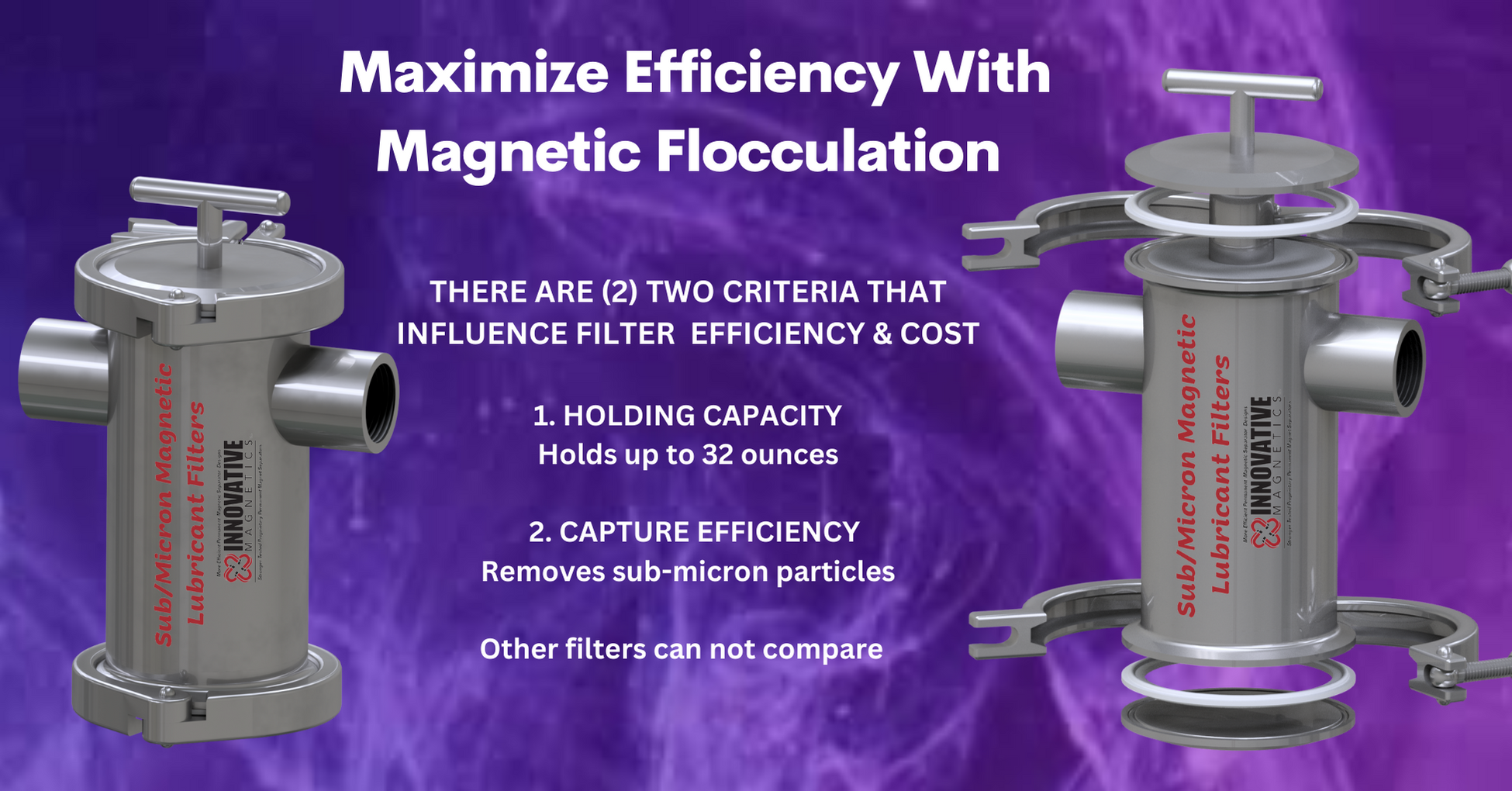

- Magnetic flocculating technological advancements prove effective remove of micron metal fines from machining fluids is now possible and an improvement over typical filter media.

- Removing these fines by magnetic flocculation & filtration allows micron ferrous particles to magnetically attract & flock together creating larger particles that enhance magnetic filter performance.

- Lubricating fluids need to be as clean as they can be to produce the most accurate parts.

- Properly designed magnetic flocculation & filtration is an economical feasible way to keep machine fluids as free of micron sized contamination as possible.

- Honing, cutting metals, grinding, and milling creates metal particles, some so small that they are not visible.

- These tiny particles can also infiltrate expensive machinery causing havoc and damage to pumps & seals, and compromise traditional filters by clogging small openings.

- Machinery kept & used in excellent condition is imperative and vital to machined part tolerances & finishes

- Savings benefits with the elimination or at a minimum, reduced traditional filter replacements.

- Additional maintenance, time & cost due to machinery components degrading can be prevented.

- Machined stainless steel fines become slightly magnetic & are removable, including non-magnetic contaminants entrapped in the removed metal fines as an additional benefit.

Invisible magnetic forces present in the submicron magnetic filter remove fines better than traditional fine spore filters

- Affordable pricing.

- Eliminates or reduces maintenance and replacement of traditional filters.

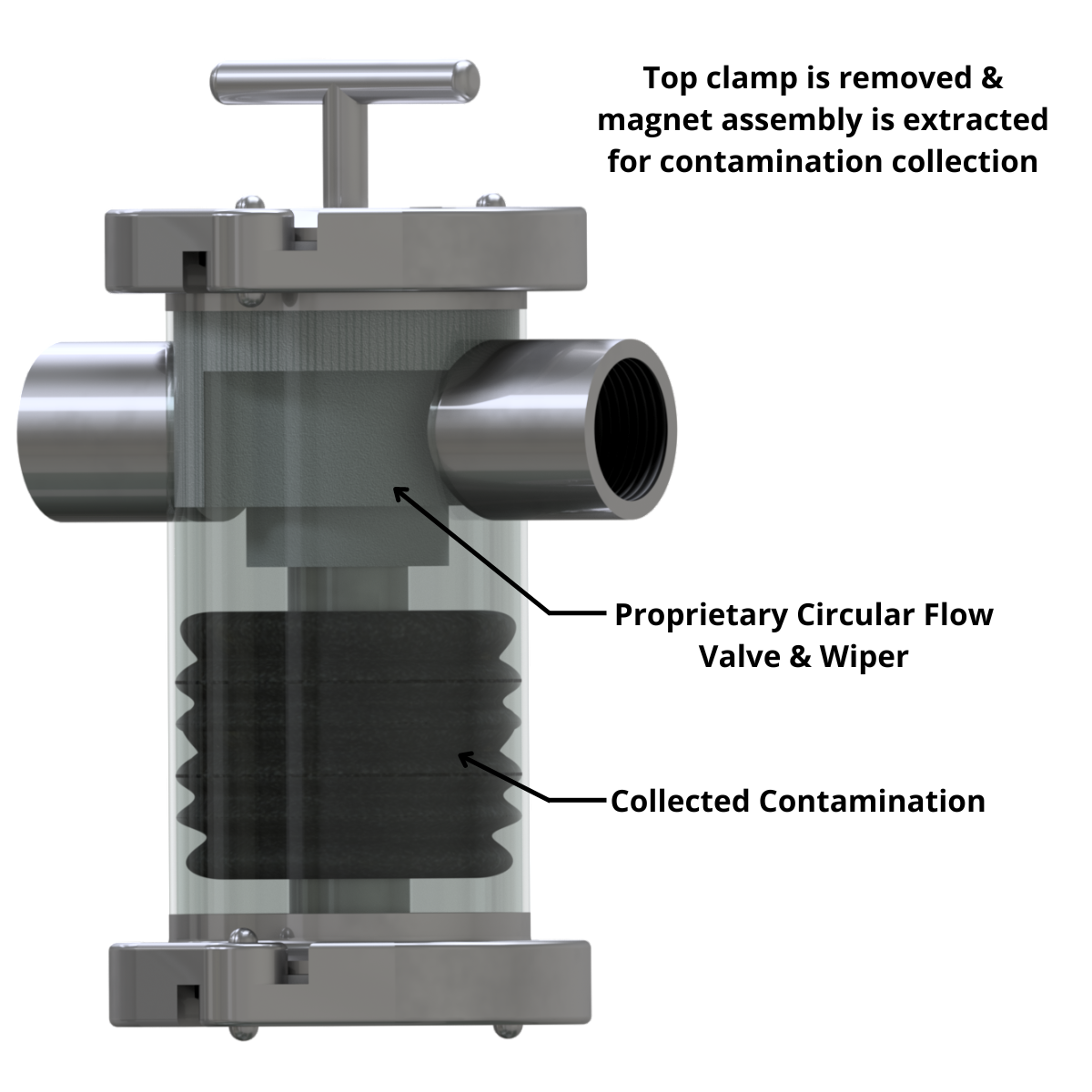

- Contamination collects around powerful magnetic tube creating a fine iron brush-like filter media that can remove non-magnetics.

- Designed to collect stainless steel chips/fines that will become partially magnetic when machined from parts.

- Easy contaminate removal.

- Saves/extends the life of standard replaceable filters or eliminates them completely.

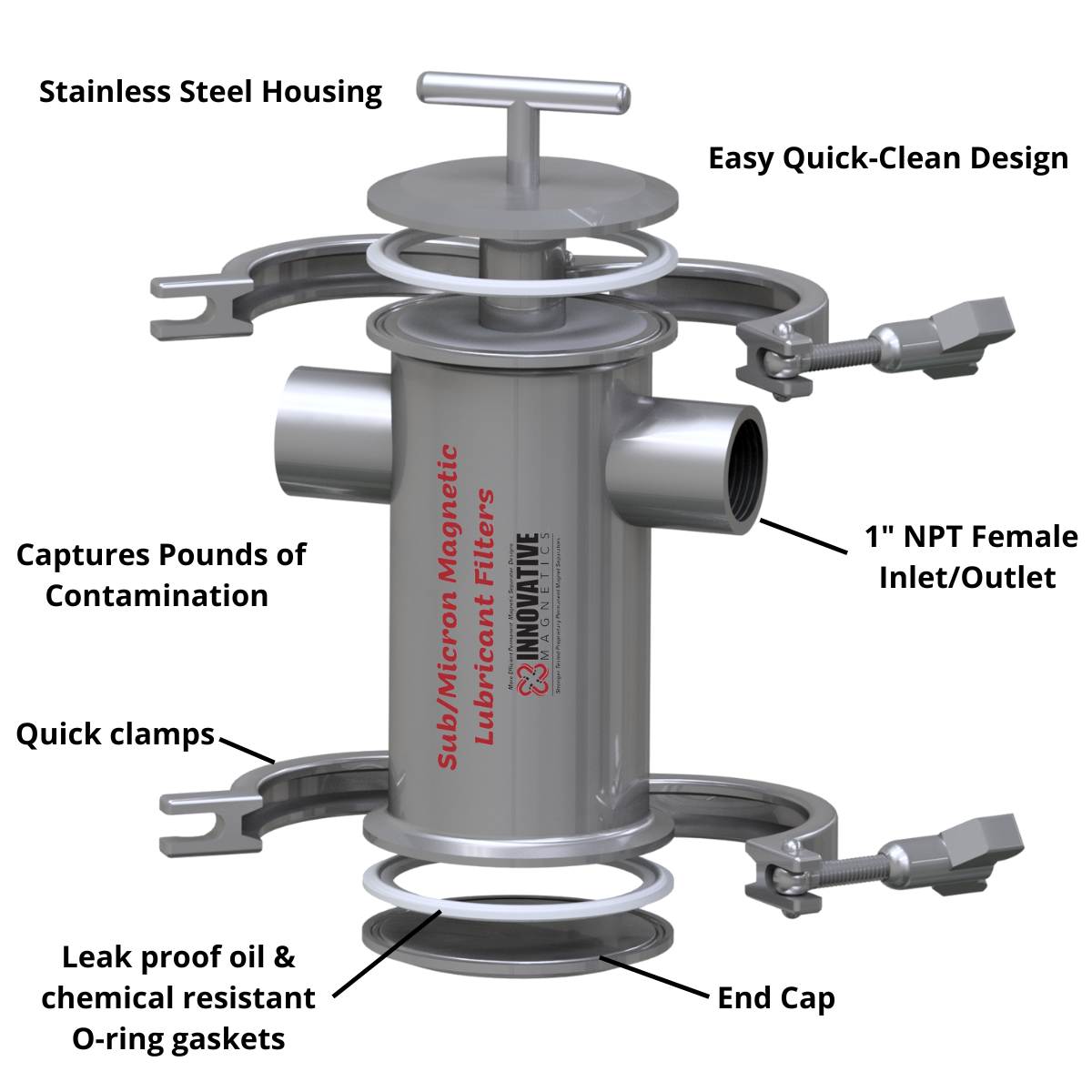

- Compact 3" diameter housings available in 8" & 14" heights.

- No plastic housings. Superior all stainless steel housing construction handling up-to 750PSI.

- Models available at 100, 250 and 750PSI

- 750PSI possible with bolt on clamps.

- To capture larger amounts of contamination, longer length housings mentioned above would be required.

- To order, simply Utilize the Get A Quote Here feature to receive an invoice for payment.

Fluids and contaminates enter the inlet where the liquid is directed internally to flow around the housing for pre-treatment. A magnetic flocculation process attracts small metal particles enlarging them by flocking together before they enter the concentrated magnetic chamber. Sub-micron particles, the most difficult size to remove, grow larger for more efficient removal by Innovative Magnetics Super Nova 52 Mega gauss 100% Rare Earth Tube Magnet.

Easy Contamination Removal From Sub-Micron Magnetic Filter

*Unit pricing subject to change dependent on fluctuating magnet imports*